Case 2 - Ceramic Sector

TYPE: AUTOMATION OF CONTROLS FOR PRODUCTION

CERTIFICATION.

CLIENT: Ceramic Company.

SITE: Sassuolo c eramic district.

PERIOD: : 2 effective monthes in 2017.

PROBLEM: The client has submitted to BEA Impianti the need to

obtain certification of the production of the raw material,

requested by important customers for the assignment of significant orders.

The certification requires the assembly and continuous

detection of some parameters, such as temperature, humidity,

storage times and use, but the existing systems did not have such

monitoring systems..

ACTIVITY PERFORMED: Compared to the problems highlighted, BEA

Impianti carried out the following activities:

-

Verification of the technical standards related to the

certification to be obtained

-

Analysis of the layout of the plant and implementation of a

feasibility study for cost containment

-

Technical design of the intervention.

-

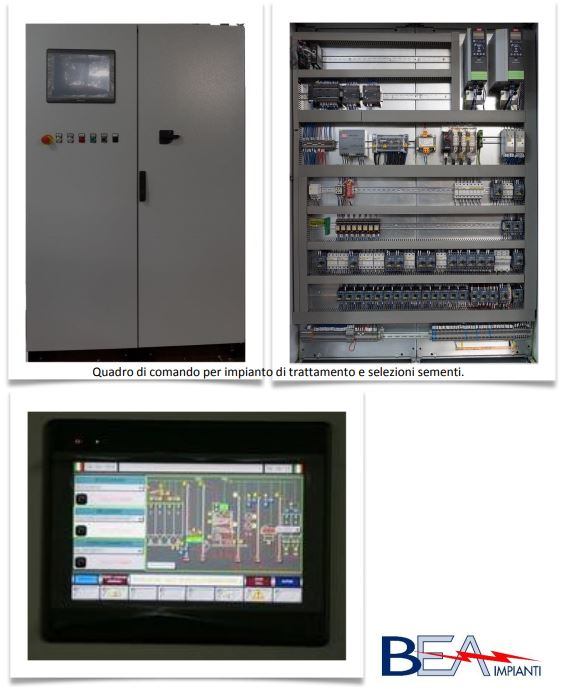

Choice of components for sensors and panel.

-

Realization of the control software.

-

Installation of sensors and transmitters in plant

environments and in the system.

-

Realization of the PLC Touch Screen control panel.

-

Installation and testing of the system.